YBM-12/0.4 Outdoor Prefabricated Substation (European Style)

Product Photos

Product Overview

The YBM-12/0.4 Outdoor Prefabricated Substation (European Style) is widely used in urban power grid renovation, residential areas, high-rise buildings, industrial and mining enterprises, hotels, shopping malls, airports, railways, oil fields, wharfs, highways, and temporary power supply facilities, suitable for both indoor and outdoor environments.

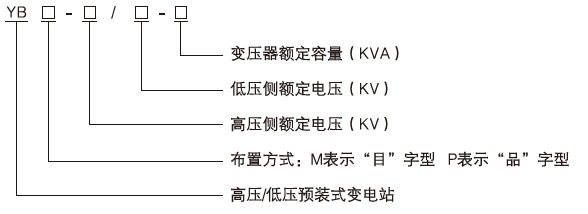

Model Meaning

Normal Operating Environment

◆ Altitude: ≤1000m;

◆ Ambient Temperature: -30℃ to +40℃;

◆ Temperature: The upper limit of the monthly average temperature is +30℃, and the upper limit of the annual average temperature is +20℃;

◆ Relative Humidity: Daily average ≤95%, monthly average ≤90%;

◆ Shock Level: Horizontal acceleration 0.4m/s², vertical acceleration 0.15m/s²;

◆ Installation Site: No severe impact, serious pollution, chemical corrosion, conductive dust, or explosive hazard locations.

◆ If normal operating conditions cannot be met, please consult with our company for a solution.

Functions and Features

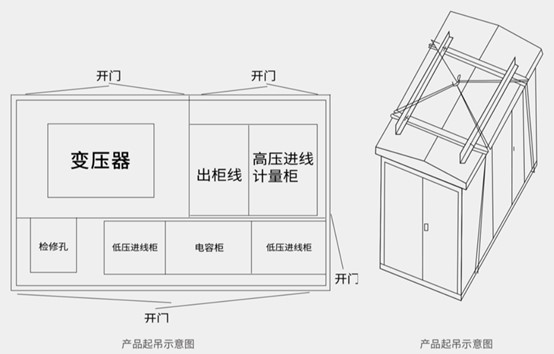

◆ The basic structure of the substation is divided into “eye” and “product” shapes, with the box frame made of high-quality channel steel and angle steel welded, which has high mechanical strength. The box is made of aluminum alloy profiles, which have good corrosion resistance. The overall aesthetic appearance, after painting and coloring, can be coordinated with the surrounding environment. The carefully designed lifting device at the bottom provides great convenience for installation, transportation, and movement.

◆ The substation has independent high-voltage rooms, transformer rooms, and low-voltage rooms, with lighting in each room automatically turning on when the door is opened. The high-voltage room is equipped with high-voltage ring network switching equipment, which can be selected according to user needs for pneumatic or vacuum load switches, and has “five-prevention” functions. When using current-limiting high-voltage fuses, if a fuse in a certain phase blows, the load switch automatically trips to prevent faults caused by single-phase operation.

◆ The transformer room uses natural ventilation and automatically controlled forced cooling air-cooling devices, with an automatically controlled exhaust system that changes with temperature, effectively controlling and reducing the internal temperature to meet operational requirements. According to user requirements, an anti-condensation device can also be used. According to user requirements, it can conveniently enter and exit from both sides of the transformer room through the main door along the track. The box material can prevent rainwater and dirt from entering, with long-term outdoor use conditions, ensuring corrosion protection, waterproofing, dust prevention, long service life, simple maintenance, and an aesthetic appearance.

◆ The transformer can use dry-type or oil-immersed transformers, and oil-immersed transformers can choose between two types with or without an oil pillow.

◆ The low-voltage room has the overall function of low-voltage complete switchgear equipment for users to select and combine at will.

◆ Shell Material: The shell materials include composite panels, stainless steel composite panels, aluminum-zinc-plated sheets, stainless steel plates, and metal carved panels.

◆ Structural Features: The high-voltage structure is reasonably compact and can be equipped with SF6, FZN57, VHC ring network cabinets, all with five-way interlocking functions.

The natural ventilation and automatic ventilation cooling system of the transformer can be used for both dry-type and oil-immersed transformers.

◆ Low-voltage Room: According to user requirements, a variety of structural power distribution schemes can be used in the low-voltage room, including power distribution, lighting distribution, automatic reactive power compensation, energy metering, and other functions, equipped with an automatic lighting system.

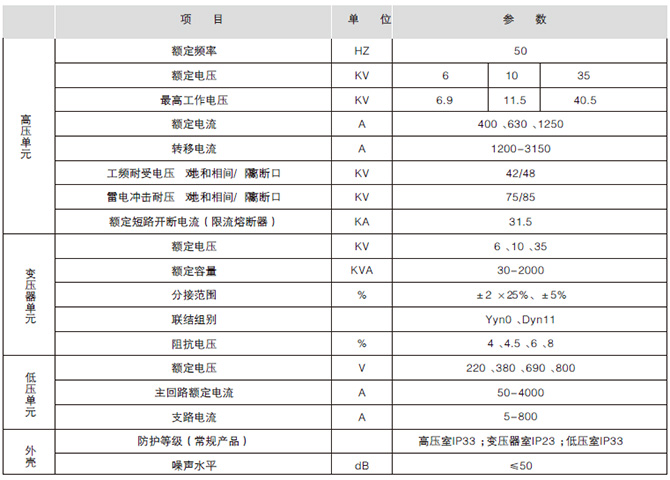

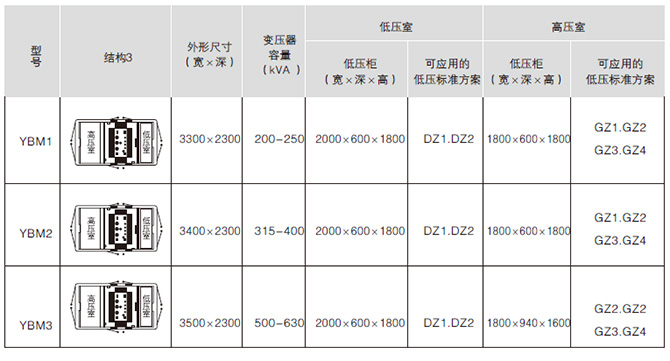

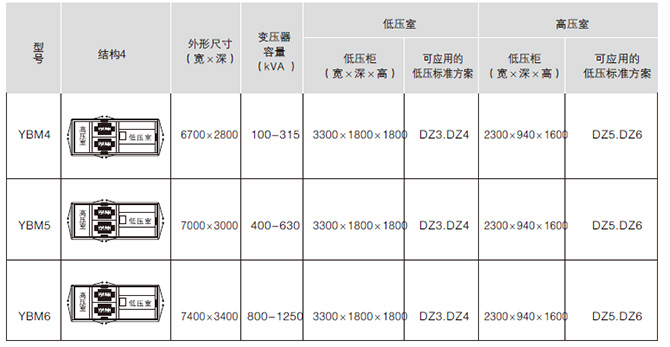

Main Technical Parameters

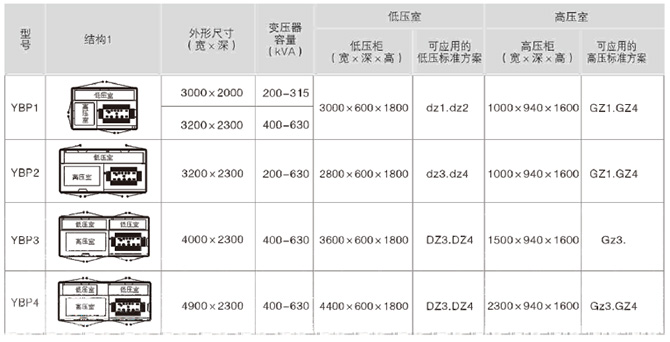

Dimensions and Structural Diagrams

We welcome global agents, distributors, retailers, and other partners to join us in developing mutually beneficial business relationships. Our products have received positive feedback from customers in many countries and regions, and we look forward to further expanding our influence. Consultation Hotline: 150-6499-9739 E-Mail: [email protected]

Installation, Use, and Maintenance

For the installation, acceptance, handover tests, operation, and maintenance of the intelligent integrated substation, in addition to the regulations required by the power department, the following points should be noted: When the customer receives the goods, they should carefully check according to the relevant regulations. For products that are not immediately installed, they should be stored in an appropriate place as stipulated by the normal operating conditions.

The product should be lifted using a special lifting device at the bottom, as shown in the figure. The product should be placed horizontally on a pre-prepared foundation, and then the gap between the product base and the foundation should be sealed with cement mortar to prevent rainwater from entering the cable room. High and low voltage cables are connected through the bottom sealing plates of the high and low voltage rooms.

After the product is installed, a reliable grounding should be done; the two main grounding terminals on the base channel steel of the substation, the neutral point and the outer shell of the transformer, the lightning arrester lower post head, etc., should be grounded separately by the installation department. All groundings should use a set of grounding devices, and the grounding resistance should be less than 4 ohms. There should be at least two grounding leads from the grounding network to the product.

Before commissioning the product after installation or maintenance, the following items should be inspected and tested:

Is the substation clean inside; is the operating mechanism flexible; Is the main electrical equipment on and off flexible and reliable; Are the on and off of the electrical auxiliary contacts reliable and accurate; Are the meter and relay actions accurate and error-free;